What is HVO?

HVO (Hydrotreated Vegetable Oil) is an advanced biofuel classified as a paraffinic fuel. It has been designed to offer a cleaner, more environmentally friendly alternative to conventional diesel. Gaining attention as a renewable energy source, HVO responds to the growing global demand for sustainable alternatives to traditional fossil fuels. With its unique properties and environmental benefits, HVO emerges as a sustainable solution for a greener future.

HVO has been developed and used as a biofuel for several decades. It was first introduced as a replacement for fossil diesel in the late 20th century. Over the years, significant milestones and discoveries have been achieved in the production and use of HVO, with researchers and engineers continuously working to optimize its production process and enhance its performance.

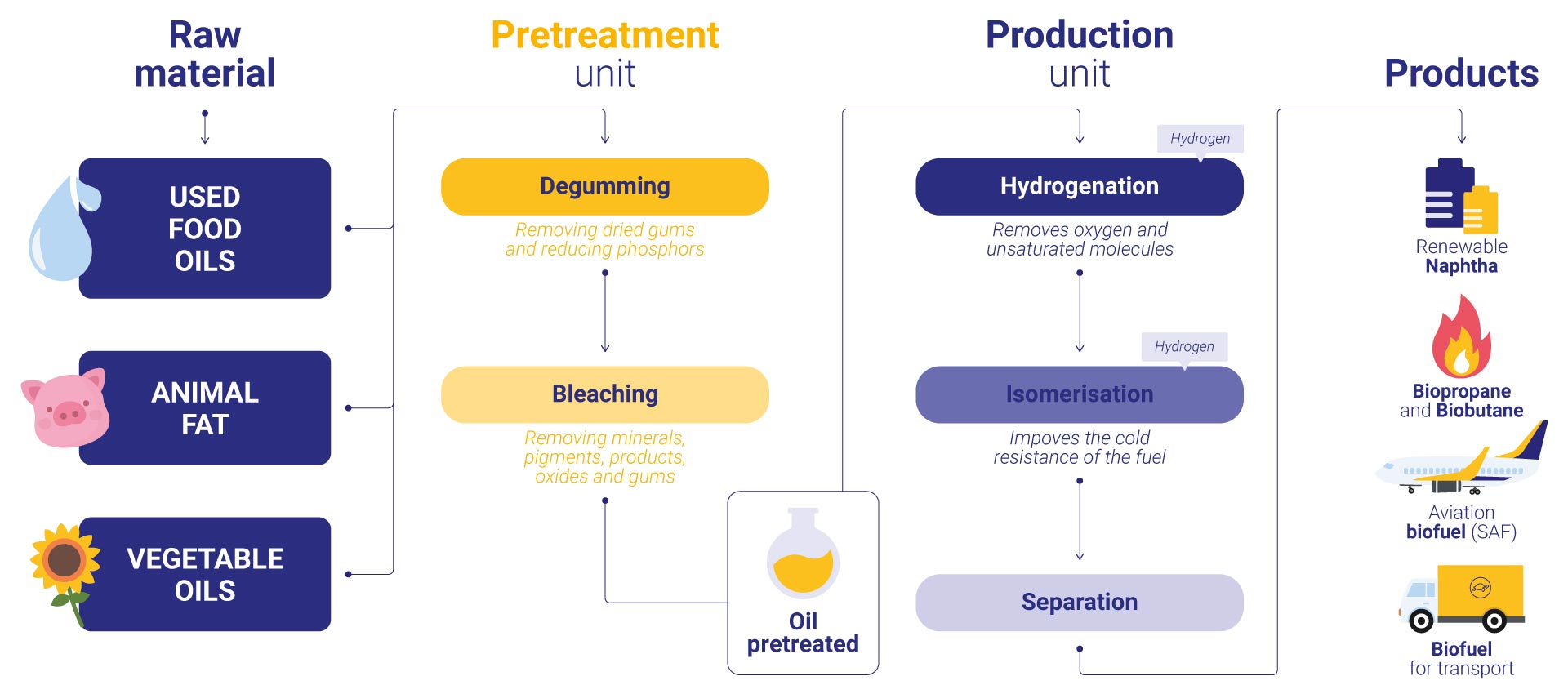

How is HVO produced?

HVO is a type of biofuel produced through a process called hydrotreatment. This involves subjecting vegetable oils, such as rapeseed oil or palm oil, to high temperatures and pressure in the presence of hydrogen gas. The process removes impurities and converts triglycerides into hydrocarbons very similar to conventional diesel fuel.

The raw materials used in HVO production typically come from renewable sources, including vegetable oils or animal fats. Known as renewable diesel, HVO underscores its sustainable nature. It is categorized as a second-generation biofuel because it is produced from non-food raw materials and offers improved environmental performance compared to first-generation biofuels.

Advantages of HVO

A key advantage of HVO is its compatibility and superior performance in existing diesel engines. Unlike some other biofuels, HVO does not require engine modifications or fuel system upgrades. It integrates seamlessly into existing infrastructure as a replacement for fossil diesel. Additionally, HVO exhibits excellent cold-weather properties, making it suitable for use in colder climates. Its high cetane number also improves engine combustion efficiency, reducing fuel consumption and potentially lowering maintenance costs.

Environmental Benefits

HVO offers significant environmental advantages over conventional fossil fuels. The hydrotreatment process removes sulfur and other impurities, resulting in a fuel with very low sulfur content. This leads to a significant reduction in harmful emissions, including sulfur dioxide and particulate matter. Furthermore, HVO has a lower carbon footprint compared to fossil diesel because it is derived from renewable raw materials. This helps mitigate greenhouse gas emissions and combat climate change.

Market Demand and Economic Impact

The demand for HVO as a biofuel is rapidly increasing, particularly in the transportation sector, where it is compatible with existing diesel engines. As governments worldwide implement policies and regulations to promote renewable fuels, HVO demand is expected to grow further. Its production also offers significant economic benefits, creating employment opportunities and boosting the growth of the biofuel industry.

HVO in Europe

Several European countries have mandated the blending of HVO with conventional diesel, leading to significant reductions in greenhouse gas emissions from the transportation sector. Large-scale projects and initiatives have successfully utilized HVO for energy production, demonstrating its versatility and efficiency as a renewable fuel source.

More and more countries are introducing HVO, often referred to as "climate-neutral diesel." This innovative fuel is produced from treated animal or vegetable fats and oils and is called "green diesel." The new alternative fuel, HVO 100 (Hydrotreated Vegetable Oil), will allow owners of older diesel vehicles to operate as before but in a much cleaner way.

What makes HVO stand out?

HVO 100 meets the DIN EN 15940 standard (paraffinic diesel) and will also be available blended with biodiesel, known as B10. Paraffinic diesel has two significant advantages:

Compatibility with all existing diesel engines without requiring any modifications to vehicles or distribution infrastructure.

It helps reduce greenhouse gas emissions by up to 90% during the fuel's life cycle compared to the fossil diesel we know.

The only "drawback" is that it costs approximately 18 cents more than conventional diesel. Several companies support using HVO biodiesel, with groups like Volkswagen and Stellantis already offering this option in their diesel-powered models. According to VW, HVO's presence in the energy market is likely to grow to a 30% share in the next decade.

HVO is among the most innovative advancements in the biofuel sector, supporting the transition to more sustainable energy solutions.