What is Biodiesel?

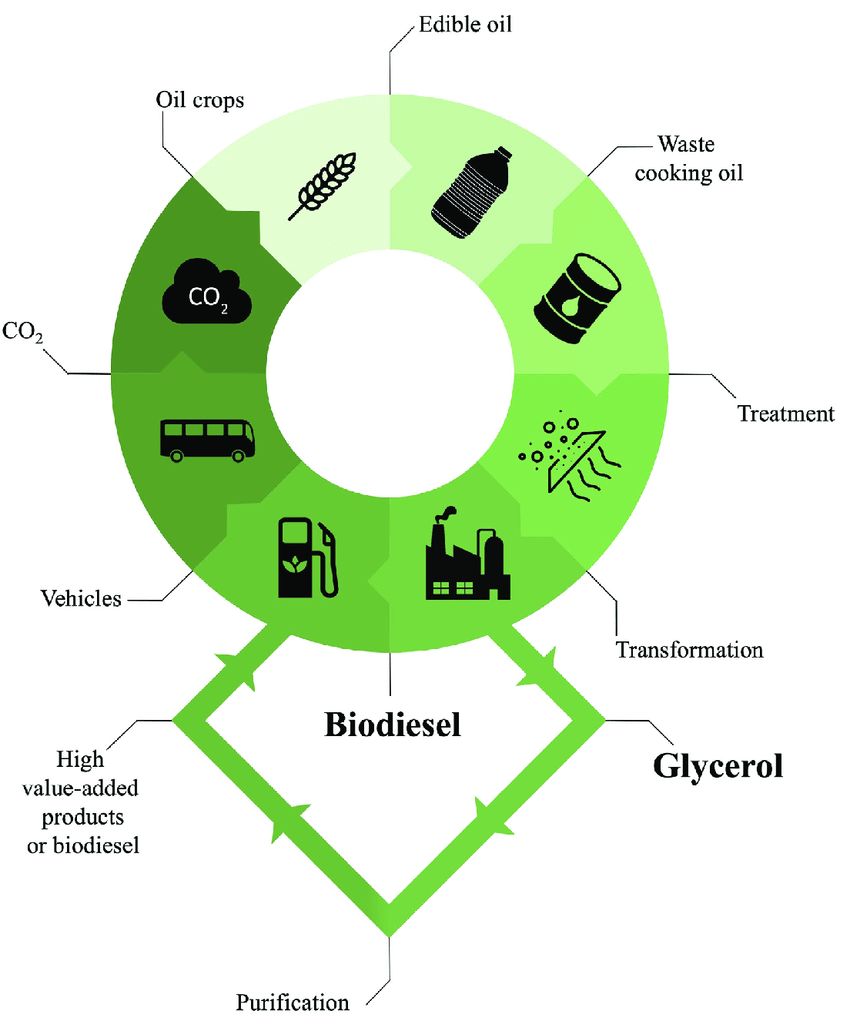

Biodiesel is a renewable fuel produced from vegetable oils, typically sunflower oil, soybean oil, rapeseed oil, etc. It can also be made from used cooking oils and animal fats. Its physicochemical properties are similar to those of diesel fuel.

Biodiesel can be used in diesel engines, either blended with diesel fuel at various percentages or in its pure form.

Why Biofuels?

The link between the greenhouse effect, which leads to global warming, and the combustion of fossil fuels is now indisputable. All credible climate prediction models differ only in the rate of climate change and the worsening of weather conditions.

The use of biodiesel in diesel engines offers significant environmental benefits, such as reducing the effects of the greenhouse effect and lowering exhaust gas emissions. Various research programs by the European Commission and independent global studies have demonstrated that consuming 1 kg of biodiesel instead of conventional diesel results in at least 1 kg less carbon dioxide (CO2) emissions. In the case of advanced biofuels, such as biodiesel derived from waste (e.g., used cooking oils, animal fats), the reduction exceeds 3 kg.

Additionally, biodiesel contains almost no sulfur and is rapidly biodegradable. The widespread use of biodiesel in the EU is a key measure to achieve greenhouse gas reduction targets set by the Kyoto Protocol. For this reason, the EU has established mandatory usage quotas for biofuels in transportation fuels for member states.

Why Biodiesel from Used Cooking Oils?

The combustion of biodiesel, like all biofuels, produces approximately the same amount of CO2 as conventional fuels. However, this amount equals the CO2 absorbed by the plant from which the biofuel originates. As a result, the CO2 balance from the plant's growth to the combustion of the produced biodiesel is neutral.

This sustainability, however, is disrupted by the CO2 emitted throughout the production cycle of biofuels, such as from the exhaust gases of agricultural machinery used for cultivation and harvesting, fertilizer production, transportation, etc. Therefore, the CO2 reduction compared to conventional fuels ranges from 50% to 90%.

In the case of using waste as raw material, such as used cooking oils and animal fats, this reduction reaches or exceeds 90%. This is because not only is the atmosphere spared from additional CO2 emissions during their production, but the environment is also protected from the adverse effects of their disposal.

Biodiesel and the Environment

- Non-toxic

- Does not contain aromatic compounds or sulfur

- Easily biodegradable

- Lower emissions of particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC)

- Significantly less contribution to greenhouse gases

As a product of renewable energy sources, biodiesel is a clean, non-toxic, and biodegradable fuel. It does not contain aromatic compounds, and its combustion in diesel engines results in very low emissions of sulfur oxides, carbon monoxide, unburned hydrocarbons, and soot. Biodiesel's sulfur content is almost zero.

Furthermore, biodiesel contains a significant amount of oxygen (approximately 10% by weight), which makes its combustion more complete. This results in exhaust gases with much lower levels of carbon monoxide (CO), unburned hydrocarbons (HC), and soot (C) compared to conventional diesel.

Additionally, biodiesel combustion does not significantly increase nitrogen oxide (NOx) emissions and reduces greenhouse gases by at least 3.2 kilograms of CO2 equivalent for every kilogram of biodiesel. This is because the CO2 released during combustion has previously been absorbed by the plant from which the raw material for its production was derived.